White 3v Smd Led 6000 - 6500 K LED Light Emitting Diode 50000 - 100000 Hours

Product Details:

Place of Origin: SHENZHEN

Brand Name: Yuhang

Certification: CE.SGS.ROHS

Model Number: YH3535W3W

Delivery Time: 5-7 work days

Payment Terms: T/T, Western Union,Paypal

Supply Ability: 8KK/Days

Detailed Product Description

| Type: | smd led | Chip Material: | InGaN |

|---|---|---|---|

| Emitting Color: | White | Luminous Intensity: | Customers' Requirements |

| Luminous Flux(lm): | 200-220LM | Power: | 2W |

| Viewing Angle(°): | 120 Degree | Color Rendering Index: | 20 |

| Color Temperature: | 6000-7000K | Operating Temperature: | -20 - 85 |

| Chip Brand: | Epistar Chip, Sanan Chip,Epileds Chip | Current: | 700mA |

| Voltage: | 3.2-3.6V | Warranty: | 2 Years |

| Lifespan: | 50000-100000Hours |

3535 Szie 1-3W 3V White 6000-6500k High Power White SMD LED Light Emitting Diode LED

Features:

Small package with high efficiency

Long operating life.

Available in white, green, blue, red, yellow, Amber

Typical color temperature: 6000-7000 K.

View angle: 120°.

Low voltage DC operated.

The product itself will remain within RoHS compliant Version.

ESD protection.

Descriptions:

The TOP 3535 series is available in soft red, orange, yellow, green, blue and white. Due to the package design, the LED has wide viewing angle and optimized light coupling by inter reflector. This feature makes the SMT TOP LED ideal for light pipe application. The low current requirement makes this device ideal for portable equipment or any other application where power is at a premium.

Applications:

Reading lights (car, bus, aircraft).

Portable (flashlight, bicycle).

Mini_accent/Uplighters/Downlighters/Orientation.

Bollards/Security/Garden.

Cove/Undershelf/Task.

Automotive rear combination lamps.

Traffic signaling/Beacons/ Rail crossing and Wayside.

Indoor/Outdoor Commercial and Residential Architectural.

Edge_lit signs (Exit, point of sale).

LCD Backlights/Light Guides.

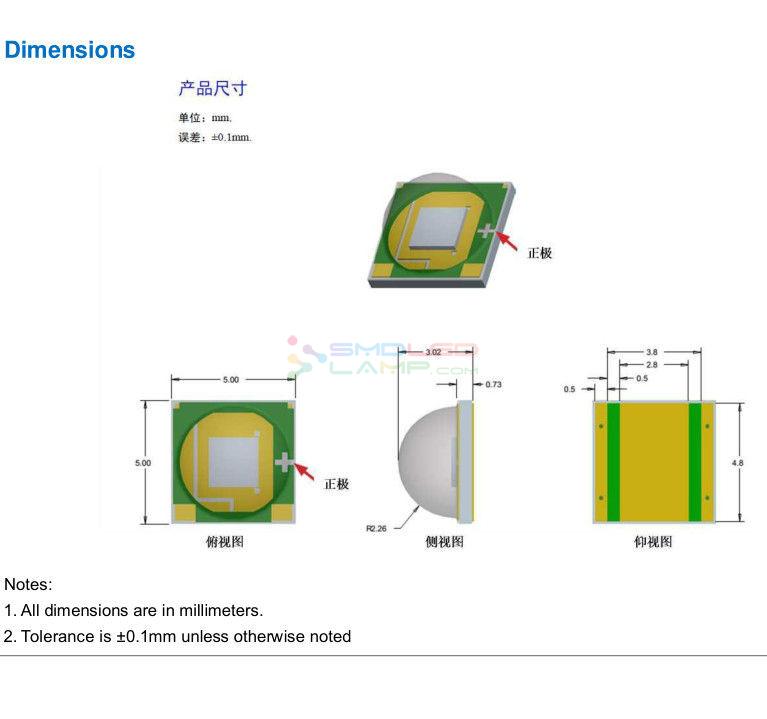

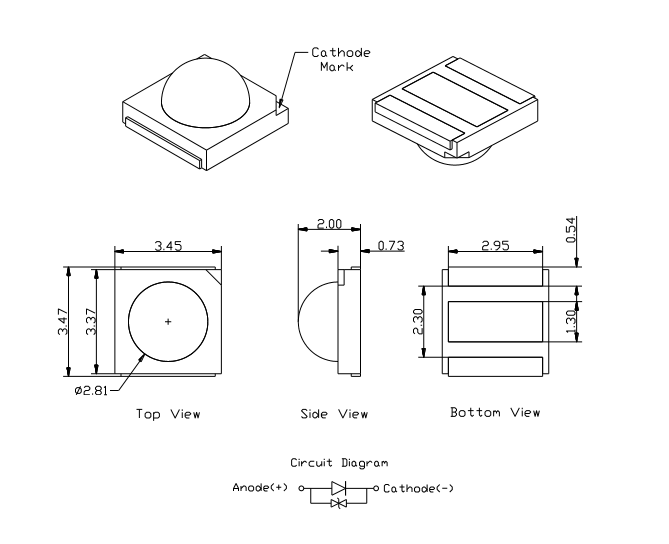

3535 Package Dimension:

| Part No. | Chip Material | Lens Color | Source Color |

| YH3535W3W | InGaN | YellowDiffused | White |

Absolute Maximum Rating @ Ta=25°C

| Parameter | Symbol | Maximum Rating | Unit | ||

| Continuous Forward Current | IF | 700 | mA | ||

| Peak Forward Current | IFp | 1000 | mA | ||

| (1/10 Duty Cycle, 0.1ms Pulse Width) | |||||

| Reverse Voltage | VR | 5 | V | ||

| Power Dissipation | PD | 3000 | mW | ||

| Electrostatic discharge | ESD | 1000 | V | ||

| Operating Temperature Range | TOPR | -25°C to +85°C | |||

| Storage Temperature Range | TSTG | -35°C to +105°C | |||

| Lead Soldering Temperature | TSOL | 360°C | |||

| (3mm from tne base of the epoxy bulb) | |||||

Electrical / Optical Characteristic @ Ta=25°C

| Parameter | Symbol | Min. | Typ. | Max. | Unit | Test Condition |

| Forward Voltage | VF | 3.2 | 3.4 | 3.6 | V | IF=700mA |

| Luminous Flux | Φ | 200 | 210 | 220 | Lm | IF=700mA |

| Color temperature | CCT | 6000 | 7000 | K | IF=700mA | |

| Reverse Current | IR | 0 | 10 | μA | VR=5V | |

| Viewing Angle | 2θ1/2 | 120 | deg | IF=700mA | ||

| Recommend Forward Current | IF(rec) | 700 | mA | |||

tolerance of measurement of forward voltage±0.1V

Typical Electrical / Optical Character Curves

( 25 ° Ambient Temperature Unless Otherwise Noted )

Reliability Tests

| Typ | Test Item | REF | Test Condition | Note | Number of | |

| e | Standard | Damaged | ||||

| Environmental | Temperature | JIS C 7021 | -20°C*30mins~25°C *5mins~ | 100 cycles | 0/100 | |

| Cycle | (1997)A-4 | 80°C * 30mins | ||||

| High Humidity | JIS C 7021 | 30°C→65°C, RH= 90% | 10 cycles | 0/100 | ||

| Heat Cycle | (1997)A-5 | 24hrs/1cycle | ||||

| Sequence | ||||||

| High | JIS C 7021 | 0/100 | ||||

| Temperature | (1997)B-10 | Ta= 80°C | 1000h | |||

| Storage | ||||||

| Humidity Heat | JIS C 7021 | Ta=60°C RH=90% | 1000h | 0/100 | ||

| Storage | (1997)B-11 | |||||

| Low Temperature | JIS C 7021 | Ta= -30°C | 1000h | 0/100 | ||

| Storage | (1997)B-12 | |||||

| Operation | DC Operating | JIS C 7035 | Ta= 25°C, IF=700mA | 1000h | 0/100 | |

| Life | (1985) | |||||

| Sequence | High Humidity | * | Ta=60°C RH=90% IF=700mA | 500h | 0/100 | |

| Low Temperature | 0/100 | |||||

| Heat Life Test | ||||||

| Life Test | * | Ta= -20°C, IF=700mA | 1000h | |||

| Destructive | Resistance to | JIS C 7021 | Tsol=260±5℃,10sec (3mm | |||

| (1997)A-11 | from the base of the epoxy | 1 time | 0/20 | |||

| Soldering Heat | ||||||

| bulb) | ||||||

| Sequence | ||||||

| Solderability | JIS C 7021 | Tsol=235 ±5℃,5sec (Using | 1 time (over | 0/20 | ||

| (1997)A-2 | flux) | 95%) | ||||

| Lead Pull/Bend | JIS C 7021 | Load 2.5N (0.25kgf) 0°→ | No | |||

| (1997)A-11 | noticeable | 0/20 | ||||

| Test | 90°→0°Bending 3 times | |||||

| damage | ||||||

*Refer to reliability test standard specification for in this line.

Cautions

The LED’s are devices which are materialized by combining blue LED’s and special phosphors. Consequently the color of the LED’s is changed a little by an operating current. Care should be taken after due consideration when using LED’s.

Moisture Proof Package:

When moisture is absorbed into package it may vaporize and expand during soldering. There is a possibility that this can cause exfoliation of the contacts and damage to the optical characteristics of the LED’s. For this reason, the moisture proof package is used to keep moisture to a minimum in the package.

Storage Conditions

Before opening the package:

The LED’s should be kept at 30°C or less and 60%RH or less. The LED’s should be used with in a year. When storing the LED’s. Moisture proof packaging with absorbent material (silica gel) is recommended. After opening the package:

The LED’s should be kept at 30°C or less and 50%RH or less. The LED’s should be soldered within 168 hours (7days) after opening the package. If unused LED’s remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material (silica gel). It is also recommended to return the LED’s to the original moisture proof bag and to reseal the moisture proof bag again. If the moisture absorbent material (silica gel) has faded away or the LED’s have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment: more than 48 hours at 65±5°C LEDGUHON LED electrode and lead free are comprised of a silver plated copper alloy .The silver surface may be affected by environments which contain corrosive gases and so on. Please Avoid conditions which may cause the LED to corrode, tarnish or discolor. This corrosion or discoloration might lower solderability or might affect on optical characteristics. Please avoid rapid transitions in ambient temperature, especially in high humidity environments where condensation can occur.

Heat Generation

Thermal design of the end product is of paramount importance. Please consider the heat generation of the LED when making the system design. The coefficient of temperature increase per input electric power is affected by the thermal resistance of the circuit board and density of LED placement on the board, as well as other components. It is necessary to avoid intense heat generation and operate within the maximum ratings given in this specification. The operating current should be decided after considering the ambient maximum temperature of LED’s.

Cleaning

It is recommended that isopropyl alcohol be used as a solvent for cleaning the LED ’s. when using other solvents, it should be confirmed beforehand whether the solvents will dissolve the package and the resin or not. Freon solvents should not be used to clean the LED’s because of worldwide regulations. Do not clean the LED’s by the ultrasonic. When it is absolutely necessary, the influence of ultrasonic cleaning on the LED’s depends on factors such as ultrasonic power and the assembled condition. Before cleaning, a pre-test should be done to confirm whether any damage to the LED’s will occur °C

Static Electricity

Static electricity or surge voltage damages the LED’s. It is recommended that a wrist band or an anti-electrostatic glove be used when handling the LED’s. All devices, equipment and machinery must be properly grounded. It is recommended that measures be taken against surge voltage to the equipment that mounts the LED’s. When inspecting the final products in which LED’s were assembled, it is recommended to check. Whether the assembled LED’s are damaged by static electricity or not, it is easy to find static-damaged LED’s by a light –on

test or a VF test at a lower current (below 1mA is recommended). Damaged LED’s will show some unusual characteristics such as the leak current remarkably increases, the forward voltage becomes lower, or the LED’s do not light at the low current. Criteria (Vf>2.0V at If=0.5mA)

Others

Care must be taken to ensure that the reverse voltage will not exceed the absolute maximum rating when using the LED’s with matrix drive. The LED light output is strong enough to injure human eyes. Precautions must be taken to prevent looking directly at the LED’s with unaided eyes for more than a few seconds. Flashing lights have been known to cause discomfort in people, you can prevent this by taking precautions during use. Also, people should be cautions when using equipment that has had LED’s incorporated into it. The LED’s described in this brochure are intended to be used for ordinary electronic equipment (such as office equipment , communications equipment, measurement instruments and household appliances) Consult YUANKE sales staff in advance for information on the applications in which exceptional quality and reliability are required, particularly when the failure or malfunction of the LED’s may directly jeopardize life or health (such as for airplanes, aerospace, submersible repeaters, nuclear reactor control systems, automobile, traffic control equipment, life support systems and safety devices). User shall not reverse engineer by disassembling or analysis of the LED’s without having prior written consent from YUANKE when defective LED’s are found, the User shall inform YUANKE directly before disassembling or analysis. The formal specifications must be exchanged and signed by both parties before large volume purchase begins. The appearance and specifications of the product may be modified for improvement without notice.

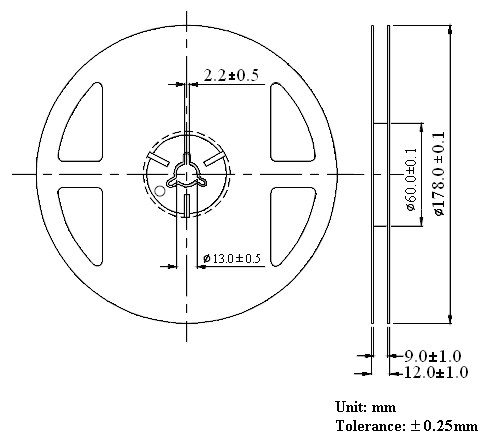

Reel Dimensions:

Carrier Tape Dimensions:

Loaded quantity 1000 PCS Per reel.

Application field

Are widely used in the LED lamp, LED bulb light, LED panel light, LED ceiling lamp, LED street light, LED lamp, miner's lamp, stage light, flashlight, lighting, lamp lighting lamps and lanterns, as well as outdoor billboards, such as electronic display, traffic lights, signs, car tail lights, LED modules, LCD back light, LED lighting lighting, LED soft/hard light bar, etc., is the better choice to replace traditional lighting light source.

INQUIRY

CATEGORIES

CONTACT US

Contact:Vicky

WhatsApp/Wechat:86-13410359515

E-mail:info@smdledlamp.com

Add:5B13-1, Futian Market Building, Fuhua Road, Futian District, Shenzhen